Video on Plastic injection molding

Plastic Injection Molding Service

Our company can make high-quality plastic injection molded parts and mold tools. We can provide both machining and finishing services to make tools from a lot of materials, and can produce 50 to 100,000+ finished parts in many of plastics.

We can ensure your tools and parts exceed your need expectations by our QA system and advanced machine. If you’re going to start your next project, upload your product design information now.

How Plastic Injection Molding Works

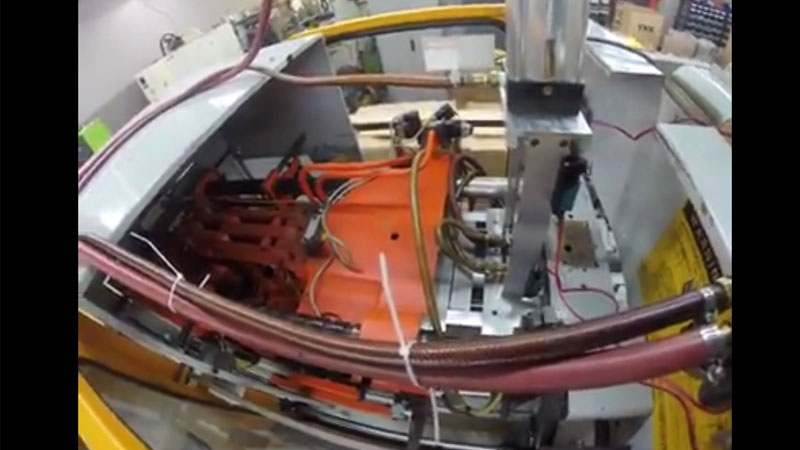

Plastic injection molding is the most popular method to produce large quantity finished plastic parts for many industrial product. Under high pressure, inject the molten resin into the cavity of a metal die and then rapidly cool it, then it is forming a solid shape. It can make the parts in few second to minutes depend on the size and complexity of the parts.

The Plastic Injection Molding Process

The molding process include below basic steps:

• Step 1. Prepare the plastic resin. They are dried to certain moisture content, if need they can be mixed with pigments or master batch colorants.

• Step 2. Put the dried pellets into the hopper of the molding machine. A reciprocating screw inside the barrel of the machine will send these pellets towards the mold.

• Step 3. The pellets are mixed and heated until fully molten in the barrel and becoming into liquid resin.

• Step 4. Then the heated mold closes automatically, under great pressure, the resin is injected through a gate and into the mold cavity.

• Step 5. Make the mold cool and then the part inside turn into solid.

• Step 6. Then open the mold opens ,you get the part ejected. New cycle begin soon.

Rapid Tooling Service

We provide hard tooling (cores and cavities) service together with different kinds of materials to better meet your need of cost , volume and production timing. You can also order special metals. Learn more about our rapid tooling service.

Plastic Injection Molding Tolerances

Nearly all plastic material will expand and contract under the impact of heat and moisture. Our tolerance guide will give general idea of this.

We will try our best to improve your designs for manufacturing. We will point out any areas where poor design may cause thermal stress, shrinkage, warping, etc. Pls refer to our design guide for more information on common defects and how to avoid them.

Unless otherwise specified, we comply with the DIN 16742 standard tolerances for plastic injection moldings.

Plastic Injection Molding Quickfacts

What plastic is used in injection molding?

Generally we can use any type of plastic in the injection molding process. There are thousands of thermoforming and thermosetting plastics that we can use your project. Check out our list of frequently used materials.

What is the plastic molding process?

Mixed the resin of the form of plastic pellets then heat it until it’s melted. The liquid plastic ,under high pressure , is injected into the hollow cavity of a mold tool and allowed to cool, becoming a solid part that is then ejected from the cavity . And then begin the next cycle.

What are the advantages of plastic injection molding?

Plastic injection molding is one of the fastest and most cost-effective way to produce hundreds of thousands of finished parts.

How long does it take to make an injection mold tool?

You might need one or two weeks to make the mold tool . It depending on the complexity of the design and heat treatment process.

See Our Past Projects

See all cases studies

info@bofongrapid.com

info@bofongrapid.com