Bofeng - A leading Rapid Prototyping Service Company

info@bofongrapid.com |

info@bofongrapid.com |

Language:

Language:

Bofeng - A leading Rapid Prototyping Service Company

info@bofongrapid.com |

info@bofongrapid.com |

Language:

Language:

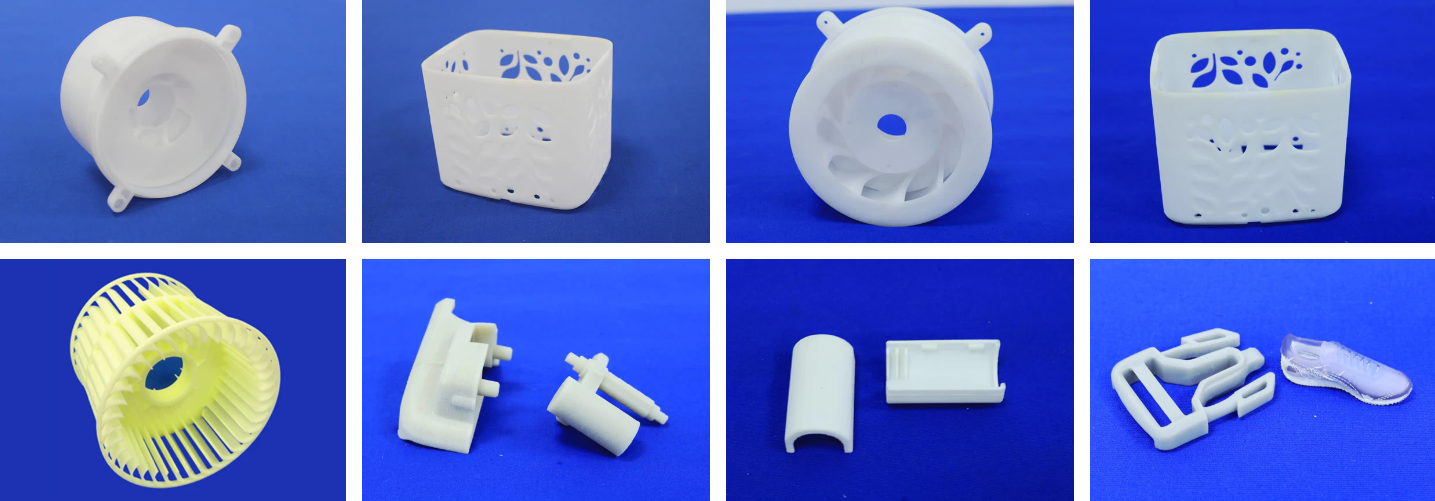

3D printing provides a fast and low-cost alternative to traditional rapid prototyping technology for architectural concepts and functional prototypes. Rapid prototyping 3D printing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process, an object is created by laying down successive layers of material until the object is created.

Advantages of rapid prototyping 3D printing

1. Better grasp the appearance of the product

Although the choice of modelling software is extensive and highly advanced, it is impossible for product designers to have a comprehensive understanding of design without a physical representation. Prototyping solves this interference and enables designers to make similar actual project models. Before an actual project appears, it is easier to find and solve these defects.

2. Instant adjustment

Rapid modelling eliminates production time and cost, which allows multiple changes during execution. Thanks to faster and cheaper adjustments, designers can generate physical representations of products and make changes at different manufacturing stages. It also benefits end consumers because they can add their input to a project and help adapt to its audience.

3. Cost-effective

3D printers of CNC machine tools can make physical models using different materials. Advanced tools can use more affordable materials such as plastics. It also does not require large amounts of energy and other resources to perform an action. In addition, both CNC machining and 3D printing are based on CAD models with high accuracy, avoiding errors and waste of resources.

4. Quick production

There is a reason for rapid prototyping. Within minutes, you can get a physical model of the product design and adjust the changes. This saves a lot of time and can be used to master the project. In addition, the simple implementation allows designers without mechanical experience to participate in the production process.

5. Reduce errors

Modern manufacturing models are usually implemented based on software and do not involve too much manual work. Automated processes help reduce human error and play a prominent role in product design. The machine executes accurately, only in CAD models.

Rapid prototyping 3D printing has advantages that other processes do not have in the initial proofing of product models, so 3D printing technology can be used to assist in the early product development and product verification. Especially for start-up companies, small maker companies, hardware development companies and other companies with insufficient start-up capital, samples made by 3D printing will be 50% cheaper than samples produced by other processes, and only need to find a reliable and long-term stable 3D Print service platform.

Bofeng is the leading rapid prototyping manufacturer. Through 3D printing, vacuum casting, CNC machining, plastic injection moulding and a range of finishing services, we can fully integrate the various steps into a coherent process that best serves you.

You may like:

Rapid Prototyping

Copyright © 2020 Dongguan City Bofeng Rapid Prototype Technology Co., Ltd. | All Rights Reserved